Process Heating

Thermal insulation for process heating is designed to generate and retain heat, minimize thermal dissipation to the environment and prevent exposure to hot surfaces in areas with personnel circulation.

Fixed System

+65°C to +250°C (149ºF to 482ºF)

To ensure thermal control and the integrity of pipes and equipment in industrial processes, we use heat tracing systems – either electric or steam – that help maintain safe operating temperatures, prevent freezing and ensure proper fluid flow.

These systems operate in a temperature range of approximately +5°C to +250°C (5ºF to 482ºF), depending on the application and process conditions. Whether through resistive electric cables or steam circulating in tracing tubes, the heating system is integrated into the thermal insulation to maximize energy efficiency and reduce heat loss.

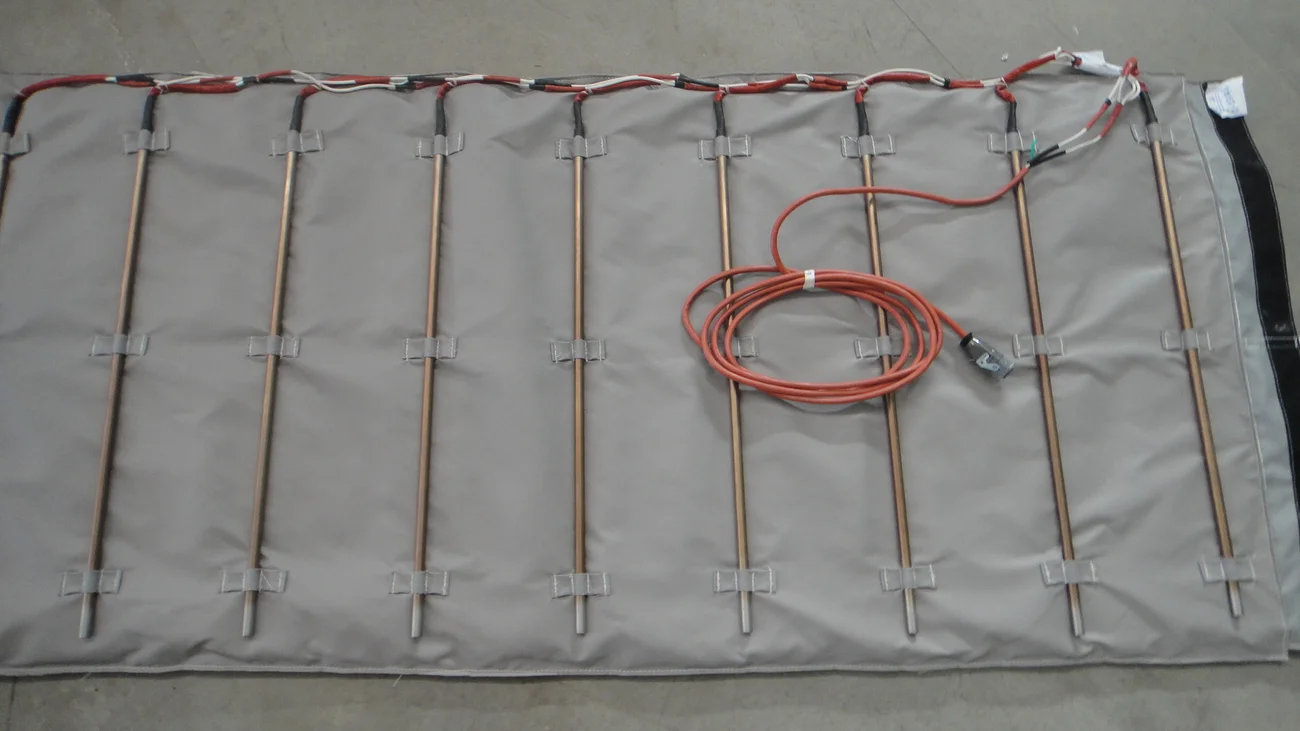

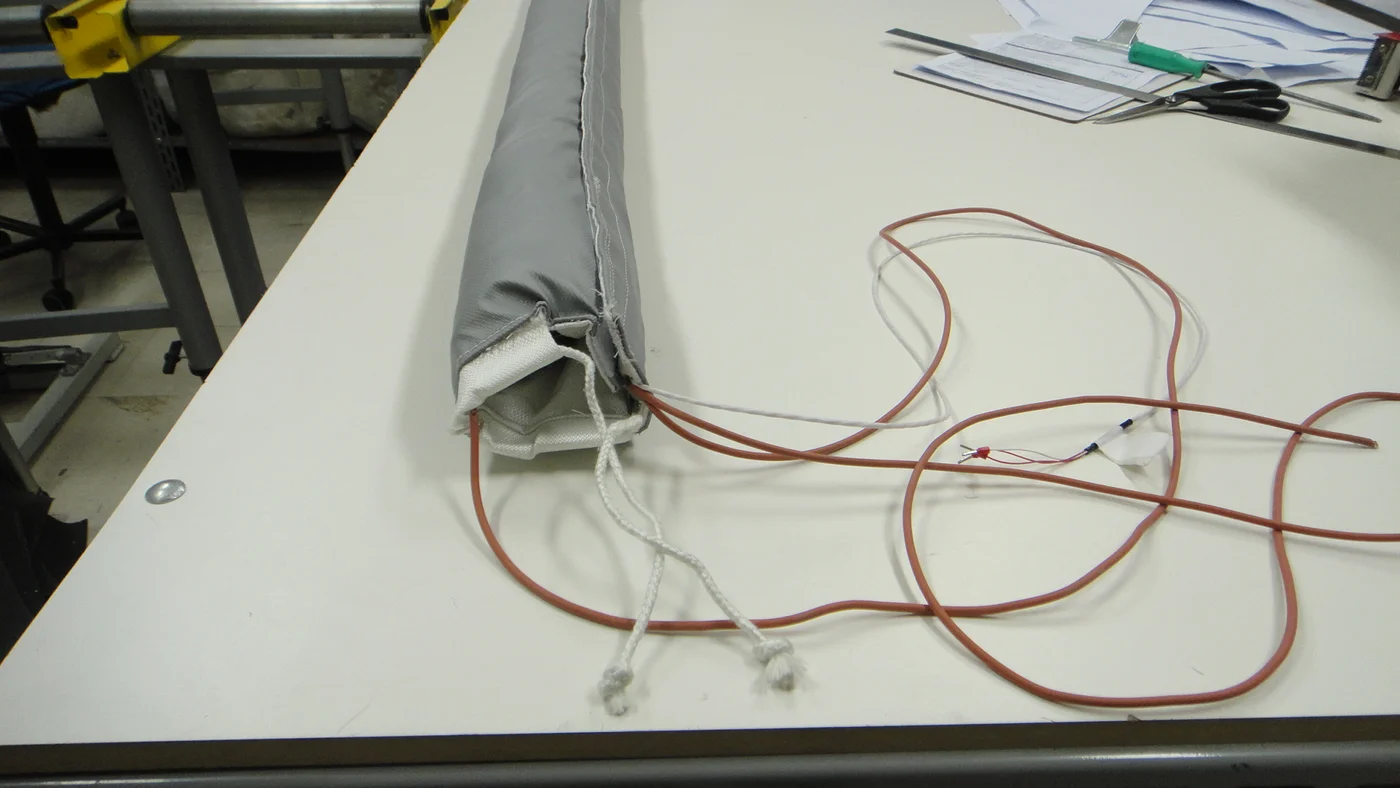

Removable & Reusable System

0°C to 500°C (32ºF to 932ºF)

Our solutions are custom-developed to suit project needs, including design for interference points and conditions that support ease of daily application, as well as temperature control and performance requirements.

This type of removable system allows for easier removal and reinstallation of the heating setup, as the tracing element is embedded in the insulation jacket.

- Warranty: 2 years

Galery

Contact us and request a quote