Corrosion testing is vital for understanding how materials react to various corrosive environments. Recognizing its importance is key to preventing failures and extending the lifespan of structures and components. We will explore the significance of corrosion testing, the methods used, the interpretation of results, and their practical applications. Discover how corrosion testing can be a valuable ally in ensuring industrial safety and efficiency.

Importance of Corrosion Testing

Corrosion testing is a critical component across various industrial sectors. Its primary importance lies in its ability to predict and prevent material degradation, ensuring the safety and efficiency of operations. In industries such as petrochemical, automotive, and civil construction, corrosion can lead to significant economic losses and even pose risks to human safety. Therefore, understanding how different materials behave in diverse corrosive environments is crucial.

Corrosion is an electrochemical phenomenon that affects material integrity over time. It can be influenced by factors such as temperature, humidity, and the presence of corrosive substances. Understanding these factors through appropriate testing helps develop solutions to mitigate their effects. For instance, selecting suitable coatings or adding chemical inhibitors during production processes can be effective strategies.

Beyond preventing failures, corrosion testing aids in selecting the most suitable materials for specific applications, optimizing durability and performance. Through methods like the Brinell hardness test, it is possible to assess material resistance, complementing corrosion analyses with data on hardness and mechanical strength. This leads to more informed decision-making in material selection.

Corrosion testing also plays a critical role in quality control. Products that fail due to premature corrosion can result in high maintenance and repair costs, as well as negatively impact a company’s reputation. Therefore, ensuring a product meets corrosion resistance standards is a vital part of quality control, contributing to long-term cost savings.

In research and development of new materials, understanding how a material behaves under corrosive influences is of central importance. It enables improvements and innovation, leading to the creation of more resistant alloys and composites. In the context of innovation, corrosion testing can indicate the viability of new products in real-world scenarios, fostering significant advancements in materials engineering.

In academic and research settings, corrosion tests are used to deepen the understanding of corrosion processes at a theoretical level. This not only leads to practical and innovative developments but also contributes to the scientific knowledge base, inspiring future studies on corrosion prevention and control methods.

Furthermore, the importance of corrosion testing is evident in situations requiring certifications and regulatory compliance. Many industries must adhere to strict regulations regarding material corrosion resistance. Test results can facilitate obtaining certifications, which are essential for entering new markets.

Finally, adopting best testing practices and analyzing corrosion test results enable industrial managers and engineers to anticipate potential issues. This allows for the implementation of corrective measures, preventing unexpected production downtime and financial losses. Additionally, it enhances safety standards, as structural failures can have catastrophic consequences.

In conclusion, corrosion testing plays a vital role in various stages of material production and development. It not only helps predict material durability and resistance under adverse conditions but is also fundamental in implementing preventive solutions that ensure operational continuity and safety across multiple industries.

Reliable Corrosion Testing Methods

Corrosion testing methods are essential for providing reliable and accurate results regarding material resistance. Several methods are used to evaluate how materials behave in corrosive environments, each with its own specificities and applications. Choosing the appropriate method depends on the type of material and its intended environment, ensuring the obtained data is relevant and useful for the desired application.

One of the most widely used methods is the salt spray test. This method simulates high-salinity conditions, exposing materials to a controlled environment with sodium chloride mist. This simulation is particularly important for industries operating in marine environments or exposed to high salinity. The results help in selecting suitable materials for critical conditions and developing effective protective coatings.

Another significant method is the corrosion potential test, which measures a metal’s propensity to corrode in a specific environment. This test provides clear insights into the surface treatments or materials needed to prevent corrosion. It offers valuable data on material longevity in real-world environments, enabling precise adjustments in production and product development stages.

The immersion test is another reliable method, where materials are submerged in a corrosive liquid for a defined period. This test is essential for determining the corrosion rate of certain materials and predicting their lifespan in situations involving direct contact with corrosive solutions. The data obtained is crucial for developing more corrosion-resistant metal alloys and composites, increasing their applicability across various industries.

Optical emission spectrometry is a more advanced technique used in conjunction with corrosion testing. It allows for detailed analysis of material composition after exposure to corrosive environments. This enables the identification of elements most susceptible to corrosion and how the material degrades. Such detailed analysis aids in formulating alloys that minimize the corrosive effects of specific chemical components.

Electrochemical analyses represent another set of methods used in corrosion testing. These include techniques like potentiodynamic polarization, which monitors electrochemical reactions occurring on the material’s surface. Such methods are effective for understanding the underlying corrosion mechanisms and the effectiveness of corrosion inhibitors, providing insights into how corrosion can be controlled.

In practical applications, choosing the appropriate testing method is crucial for obtaining reliable results in a testing laboratory. Each test has its specialties and limitations, and they are often used in combination to gain a comprehensive understanding of material behavior. Moreover, testing methods must be continuously calibrated and validated to ensure consistent and accurate results that faithfully reflect real-world conditions.

Advancements in testing methods and their adaptability to specific scenarios drive development and innovation in the field of materials science. Reliable results from these methods not only help improve existing materials but also enable the discovery of new compositions that better resist corrosion. Thus, the impact of these methods extends from academia to industry, significantly contributing to the sustainability and efficiency of production processes.

The precision and reliability of testing methods are essential not only for predicting component lifespan but also for avoiding unexpected maintenance costs and safety risks. Companies that invest in reliable testing methods tend to gain a competitive edge by offering higher-quality, more durable products to their customers.

How to Interpret the Results

Interpreting corrosion test results is a crucial step in transforming data into actionable knowledge. Correct interpretation allows for understanding the effectiveness of materials in resisting corrosion under specific conditions, guiding product improvements and preventive strategies. Analyzing results carefully can be complex, but understanding the underlying principles simplifies the process and ensures informed decisions.

First, it is important to understand the standard metrics used in result reports. Parameters such as the corrosion rate, measured in millimeters per year (mm/y), provide a clear view of how quickly a material deteriorates in a specific corrosive environment. A high rate may indicate the material’s unsuitability for that environment, prompting alternative selections or surface treatments.

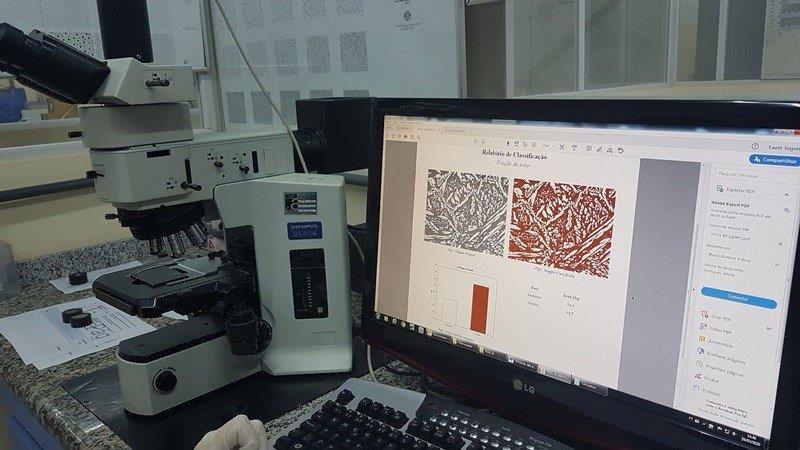

Visual characterization of the surface after exposure offers insights into the types of corrosion occurring, such as pitting or uniform wear. Photographs and detailed descriptions help identify corrosion patterns, informing the severity and extent of damage. This qualitative step is as essential as quantitative analysis, as it guides engineers in understanding the precise conditions under which corrosion occurs.

Data from technological analyses, such as optical emission spectrometry, also play a significant role in interpreting corrosion test results. These analyses provide detailed information about the material’s chemical composition and changes after testing. Understanding which chemical elements were most affected can indicate necessary protective mechanisms and material vulnerabilities.

In comparative studies, where different materials or surface treatments are tested under the same conditions, it is important to observe variations in results. Comparisons can indicate which materials perform better or which combination of corrosion inhibitors and coatings is most effective. Statistical analyses can help confirm whether observed differences are statistically significant or result from inherent variations in the testing process.

Interpreting results in a broader context is crucial, considering the real operational environment where the material will be applied. Factors such as temperature, pressure, and the presence of other elements can alter corrosive behavior in uncontrolled environments compared to a testing laboratory. Therefore, test results must always be contextualized within the intended application scenario.

A critical analysis of corrosion test results should also consider inaccuracies or errors in the testing methods used. All methods have inherent limitations, and understanding these helps interpret data more realistically. This way, engineering decisions can be made with a clear understanding of the uncertainties involved.

Well-crafted documentation and reports are indispensable for sharing results and facilitating communication among different teams within an organization. Detailed reports ensure the entire test history is communicated, enabling subsequent reviews and effective monitoring of any changes in corrosive behavior over time.

Finally, interpreting corrosion test results requires an integrated approach, combining technical-scientific knowledge with current industrial practices. Materials engineers, chemists, and QUALITY analysts must collaborate to develop continuous improvement strategies based on test conclusions. With the constant evolution of corrosion knowledge, interpretations should be regularly revisited to reflect advancements in materials science.

In summary, the ability to correctly interpret corrosion test results not only helps extend the lifespan of products and structures but also protects investments and ensures user safety. A comprehensive and contextual understanding of these results empowers organizations to align their production with best practices, ensuring constant quality and innovation.

Practical Applications and Industrial Relevance

Corrosion testing plays a crucial role in various industries, resulting in profound practical implications and significant industrial relevance. A detailed understanding of how materials behave in corrosive environments not only prevents structural failures but also optimizes production processes and materials, enhancing safety and cost-efficiency.

The oil and gas sector is one of the primary beneficiaries of corrosion testing. Structures in this industry are constantly exposed to highly corrosive environments, both offshore and onshore. Corrosion testing enables the development of materials better adapted to these extreme conditions, increasing the durability of pipelines, platforms, and other equipment. This significantly reduces the risk of failures and leaks, protecting both financial investments and the environment.

In the automotive sector, corrosion is a constant concern. Metal components exposed to varying climates can corrode over time, impacting vehicle longevity and safety. Corrosion testing helps develop protective coatings and select metal alloys that ensure the necessary resistance without compromising vehicle weight and efficiency. These advancements are essential for meeting demands for more durable and sustainable vehicles.

The maritime industry also greatly benefits from corrosion testing. Ships and other naval structures operate in a saline environment, one of the most challenging in terms of corrosion. Through corrosion testing, naval designers can select materials and coatings that extend the lifespan of ships and offshore platforms, ensuring operational safety and reducing maintenance costs.

In civil construction, corrosion testing guides decisions on which materials to use in bridges, buildings, and other infrastructures exposed to corrosive environmental factors. Extending the lifespan of these structures reduces maintenance costs and enhances building safety. This is particularly crucial in coastal regions, where proximity to the sea intensifies the presence of salt in the environment, increasing corrosion potential.

Beyond specific applications in industrial sectors, the relevance of corrosion testing extends to any field dealing with material durability. Whether in developing new products, improving existing ones, or ensuring quality control, these tests are central to ensuring materials meet current safety and performance standards.

Technological innovations have expanded the practical applications of corrosion testing. Combining these tests with predictive modeling technologies allows for anticipating material behavior in untested conditions, minimizing the need for field tests and accelerating product development.

Moreover, using corrosion tests in conjunction with other technical analyses, such as those in a testing laboratory, provides a more comprehensive understanding of material performance. Integrating corrosion test data with resistance and composition information offers a holistic view of a material’s suitability for specific applications.

In many cases, corrosion test results are incorporated into international regulations and standards, underscoring their ongoing importance in establishing industrial standards. Compliance with these standards not only ensures safety but also enhances competitiveness in the global market.

The challenges faced by various industries drive innovation in materials science, with corrosion testing at the forefront of these advancements. With the growing demand for sustainable and cost-effective solutions, the importance of corrosion testing is set to increase, setting new benchmarks for material resistance and durability.

The practical applications of corrosion testing go beyond simple laboratory tests, forming an integral part of robust business strategies, delivering large-scale cost savings, and ensuring safety across numerous industrial operations.

After exploring the key aspects of corrosion testing, it is evident that it plays a critical role in protecting and ensuring the durability of materials across various industrial sectors. Whether through the importance of testing, the methods used, the interpretation of results, or practical industrial applications, understanding corrosion is fundamental to innovation and ensuring the safety and efficiency of structures and components. We invite you to deepen your knowledge about how these tests can benefit your specific industrial sector.

Share your experiences with us or send a message to learn more; we are eager to enrich this conversation and contribute to the success of your operations. And you, how do you plan to apply these ideas in your industrial strategy? Think about it and start making a difference today!