Non-destructive mechanical tests are essential for ensuring the integrity and durability of materials without damaging them. This article explores the main methods, their advantages, applications in different industries, and how to choose the appropriate method for your specific needs. Keep reading to learn about the techniques and benefits of these tests.

1. Main Non-Destructive Mechanical Tests

Non-destructive mechanical tests are fundamental techniques for evaluating the integrity and properties of materials without causing damage. They play a crucial role in various industries, helping to ensure that materials maintain their characteristics and performance over time. Here are some of the main non-destructive mechanical testing methods used:

One of the oldest and most widely applied tests is the Brinell hardness test. This method involves applying a specific load through a standard diameter sphere in contact with the surface of the tested material. The diameter of the indentation left by the sphere is measured to determine the material’s hardness. This test is popular due to its simplicity and ability to provide consistent results, ideal for evaluating metallic materials and their alloys.

The Charpy impact test is another crucial method. In this test, a standardized material sample is fixed on a base, and a pendulum is released to strike and fracture the sample. This test measures the energy absorption of the material during fracture, reflecting its toughness and behavior under impact conditions. It is widely used in the analysis of structural materials that may be subjected to impact loads.

Optical emission spectrometry is an advanced technique that allows qualitative and quantitative analysis of the elements present in a sample. Using an electric arc or flame, the sample is vaporized, and the light emission from different elements is measured and analyzed. Essential in sectors such as metallurgy and geology, this non-destructive method is valued for its accuracy and real-time analysis capabilities.

Non-destructive mechanical testing methods continue to evolve and diversify, reflecting the growing needs of modern industries. Ultrasound, for example, uses high-frequency sound waves to detect internal flaws and discontinuities in solid materials. This method is highly effective for identifying defects that are not visible to the naked eye, being widely applied in civil engineering, aerospace, and the automotive industry.

Additionally, X-ray analysis is a well-known technique that uses radiation to visualize the internal structure of a material. This method is commonly used in welds and critical components, providing detailed images without damaging the inspected material. Computed tomography, an advancement of this technique, allows for detailed three-dimensional images, further increasing the accuracy of analyses.

Other advanced techniques include thermography, which uses infrared cameras to detect temperature variations on a material’s surface. These variations can indicate the presence of internal flaws, corrosion, or other defects. This technique is widely applied in predictive maintenance and the inspection of critical structures and equipment.

Non-destructive mechanical tests remain a vital and dynamic area, essential for ensuring the safety, reliability, and performance of materials in various sectors. Continuous innovation and the development of new technologies promise to further enhance the effectiveness of these methods, providing more accurate and comprehensive tools for material analysis.

2. Advantages of Non-Destructive Mechanical Tests

Non-destructive mechanical tests (NDT) offer a range of significant advantages that make them indispensable in various industries. These methods allow for extensive evaluation of material properties and integrity without damaging them, ensuring they can continue to be used after testing. Here are some of the main advantages of these tests:

Firstly, one of the greatest advantages of the Charpy impact test is material preservation. Unlike destructive methods, NDT maintains the sample’s integrity, allowing for reuse and continuous evaluation. This is particularly advantageous in applications where the tested material is expensive or rare, avoiding waste and saving resources.

Additionally, non-destructive mechanical tests offer high accuracy in defect detection. Techniques such as ultrasound and radiography can identify internal and surface flaws that would not be detectable to the naked eye. This accuracy is crucial for ensuring the safety and reliability of critical components in sectors such as civil construction, aerospace, and automotive.

Another significant advantage is the ability to perform inspections while equipment is in operation. This minimizes downtime, increasing operational efficiency. For example, optical emission spectrometry allows for immediate and accurate analysis without the need to take equipment out of service. This is extremely useful in industries where downtime can result in significant financial losses.

NDT also offers the possibility of continuous monitoring and predictive maintenance. Techniques such as thermography and ultrasonic analysis can be used to constantly monitor the condition of materials and predict failures before they occur. This not only extends equipment lifespan but also improves safety, preventing accidents caused by unexpected failures.

In terms of costs, non-destructive mechanical tests are also advantageous. Although some methods may require sophisticated equipment, the savings from preventing failures, efficient maintenance, and reduced material waste more than offset the initial investment. Therefore, these methods are a cost-effective choice in the long term.

Flexibility is another notable advantage. NDT can be applied to a wide variety of materials, including metals, ceramics, polymers, and composites. This makes these tests extremely versatile and applicable in various industrial contexts. From weld inspections to the analysis of advanced composite materials, these methods provide comprehensive solutions for various needs.

Finally, non-destructive mechanical tests contribute significantly to quality control. The ability to fully inspect finished products without damaging them ensures that quality standards are maintained. Detecting and correcting defects before products reach consumers reduces complaints and enhances the company’s reputation.

In summary, non-destructive mechanical tests offer several advantages that make them indispensable in material inspection and maintenance. They preserve sample integrity, provide high accuracy, enable in-service inspections, allow continuous monitoring, are cost-effective, flexible, and contribute to quality control. These characteristics make these methods widely used and valued in different industries.

3. Applications in Different Industries

Non-destructive mechanical tests (NDT) are vital in many industries, offering critical solutions for inspection, maintenance, and quality assurance. Let’s explore how these methods are applied in key sectors:

In the civil construction sector, NDT is used to ensure the safety and durability of structures. Techniques such as ultrasound and radiography are applied to verify weld integrity, detect cracks in concrete, and monitor the quality of construction materials. The use of these techniques ensures that structures can withstand the loads they were designed for, increasing public safety and preventing catastrophic failures.

In the aerospace industry, safety is paramount, making NDT indispensable. Advanced methods, such as the Brinell hardness test and computed tomography, are used to inspect critical components like wings, fuselages, and jet engines. These tests help detect porosities, cracks, and other anomalies that could compromise the aircraft. Additionally, continuous monitoring enables predictive maintenance, ensuring all components are in optimal operating condition.

In the automotive industry, NDT is applied at all stages of manufacturing, from raw material inspection to quality control of finished products. The Charpy impact test, for example, is used to test the material’s resistance to fracture, ensuring occupant safety in the event of a collision. Methods like ultrasonic analysis ensure that critical components, such as axles and suspension systems, are free of defects that could lead to in-service failures.

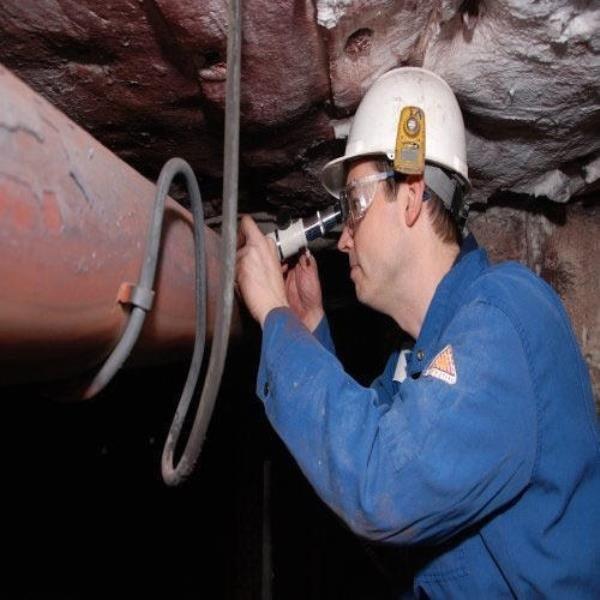

In the petrochemical industry, the integrity of pipelines and pressure vessels is essential to prevent leaks and explosions. Techniques such as optical emission spectrometry are widely used to analyze material composition and detect signs of corrosion or degradation. Ultrasonic inspection is applied to detect internal cracks and wall thickness in pipelines, ensuring operational continuity without accident risks.

In the naval industry, NDT ensures that ships and platforms are in safe operating condition. Weld integrity in hulls and vessel infrastructure is regularly monitored with techniques such as radiography and ultrasound. These methods help identify failures that could lead to leaks or other serious structural issues, protecting lives and the environment.

Beyond these sectors, NDT also has applications in the electronics industry, where component reliability is critical. X-ray analysis is used to inspect welds and internal connections in circuits, ensuring they are free of defects. This is especially important in the manufacture of medical devices and communication equipment, where even small failures can have significant consequences.

Non-destructive mechanical tests are also vital for energy production, both in nuclear power plants and wind farms. In nuclear plants, methods like ultrasonic inspection and X-ray analysis ensure reactor components are in perfect condition, preventing radiation leaks. In wind farms, constant inspection of rotor blades and transmission systems helps maintain efficiency and safety in operations.

In summary, NDT is essential in various industries, ensuring the integrity, safety, and efficiency of materials and components used. Its widespread application and ability to detect flaws without causing damage make these methods an irreplaceable choice for predictive maintenance, quality control, and extending product lifespan.

4. How to Choose the Right Method

Choosing the appropriate non-destructive mechanical testing (NDT) method for a specific application can seem challenging due to the variety of techniques available and the different needs of each project. However, understanding the characteristics and benefits of each method can help make an informed decision. Here are some guidelines for selecting the most suitable NDT method for your needs:

The first step is to understand the nature of the material to be tested. Metallic materials, for example, can be effectively tested using the Brinell hardness test, which measures the material’s resistance to penetration. This method is ideal for alloys and pure metals, providing a clear indication of the material’s hardness and strength without causing significant damage. It is particularly useful in industries dealing with heavy metals and their alloys.

The nature and type of flaws that need to be detected also play a crucial role in choosing the appropriate method. To evaluate a material’s toughness, for example, the Charpy impact test is an excellent choice. It is designed to measure a material’s ability to absorb energy during an impact and is ideal for identifying brittleness at various temperatures. This makes the Charpy impact test particularly important in structural applications where materials may be subjected to impact loads.

The precision and depth of inspection required must also be considered. For accurate chemical compositions, optical emission spectrometry is a highly effective method. It allows for detailed and precise analysis of the elements present in the material without destroying it. This method is widely used in quality control processes where the exact composition of the material is critical, such as in the production of steels and special metallic alloys.

The accessibility of equipment and ease of use are also important factors. If the inspection needs to be performed in the field, portable methods like ultrasound or thermography may be more practical. These methods do not require large facilities and can be easily transported to different locations, facilitating real-time inspection and maintaining normal industrial operations. Ultrasound is particularly useful for detecting internal flaws without requiring cutting or sectioning of structures.

Another vital factor to consider is the cost and availability of equipment. While some methods, such as radiography and computed tomography, offer highly detailed images, they can be expensive and require specialized operators. More accessible methods like visual inspection or surface hardness tests may be sufficient for routine applications where detailed analysis is not necessary. The cost-benefit must always be evaluated, especially in large-scale operations.

Safety is also a crucial consideration, especially when working in high-risk environments. Techniques that use radiation, such as radiography, require specific precautions to protect workers from exposure. Methods like ultrasonic inspection and thermography are safer and may be preferred in environments where operator safety is a predominant concern.

Finally, it is essential to consider the specific application and regulatory requirements. In sectors such as construction and aerospace, regulations may require the use of specific methods to ensure compliance with safety and quality standards. Meeting these regulations not only ensures safety but also avoids legal and financial issues arising from non-compliance.

Therefore, when selecting the appropriate non-destructive mechanical testing method, it is essential to consider the nature of the material, the type of defects to be detected, the precision required, equipment accessibility, cost, safety, and regulatory requirements. A thorough evaluation of these factors will help choose the most appropriate technique, ensuring that materials are tested efficiently, safely, and cost-effectively.

After exploring the main topics discussed throughout this article, it is evident that non-destructive mechanical tests play a crucial role in maintaining the integrity and durability of materials in various industries. From identifying the most effective methods and their significant advantages to their diverse industrial applications and the criteria for selecting the appropriate method, the importance of these tests cannot be underestimated.

We invite you to apply the knowledge gained about non-destructive mechanical tests in your own operations, ensuring greater safety, accuracy, and efficiency. Share your experiences or questions, send us a message; we are eager to hear your opinion and continue this enriching conversation.

And you, how do you plan to apply these ideas in your daily work? Think about it and start making a difference today!