Advanced Non-Destructive Testing

Advanced Non-Destructive Testing (NDT) methods represent a significant evolution in structural integrity assessment, offering greater precision, deeper inspection capabilities and enhanced analysis of complex materials and geometries. Techniques such as Phased Array Ultrasonic Testing (PAUT), Time of Flight Diffraction (TOFD) and ultrasonic corrosion mapping enable detailed identification of discontinuities, ensuring accurate diagnostics for predictive and corrective maintenance.

At Priner, we apply advanced technologies tailored to various industrial needs, including:

Corrosion Detection and Mapping

- Phased Array Ultrasonic Testing (PAUT) and thickness mapping (C-Scan) to detect localized and widespread corrosion on metallic surfaces, including tanks, piping, and large-scale structures.

Detection and Sizing of Mechanical Discontinuities

- Inspections using Time of Flight Diffraction (TOFD), Phased Array (PAUT), Total Focusing Method (TFM) and Phase Coherence Imaging (PCI) to locate, size and characterize cracks, inclusions, and weld or structural discontinuities.

Inspection of Tubes and Heat Exchanger Bundles

- Application of specialized techniques such as Eddy Current Testing (ECT), Remote Field Testing (RFT) and Internal Rotary Inspection System (IRIS) to assess the integrity of tubes and coils in heat exchangers and boilers.

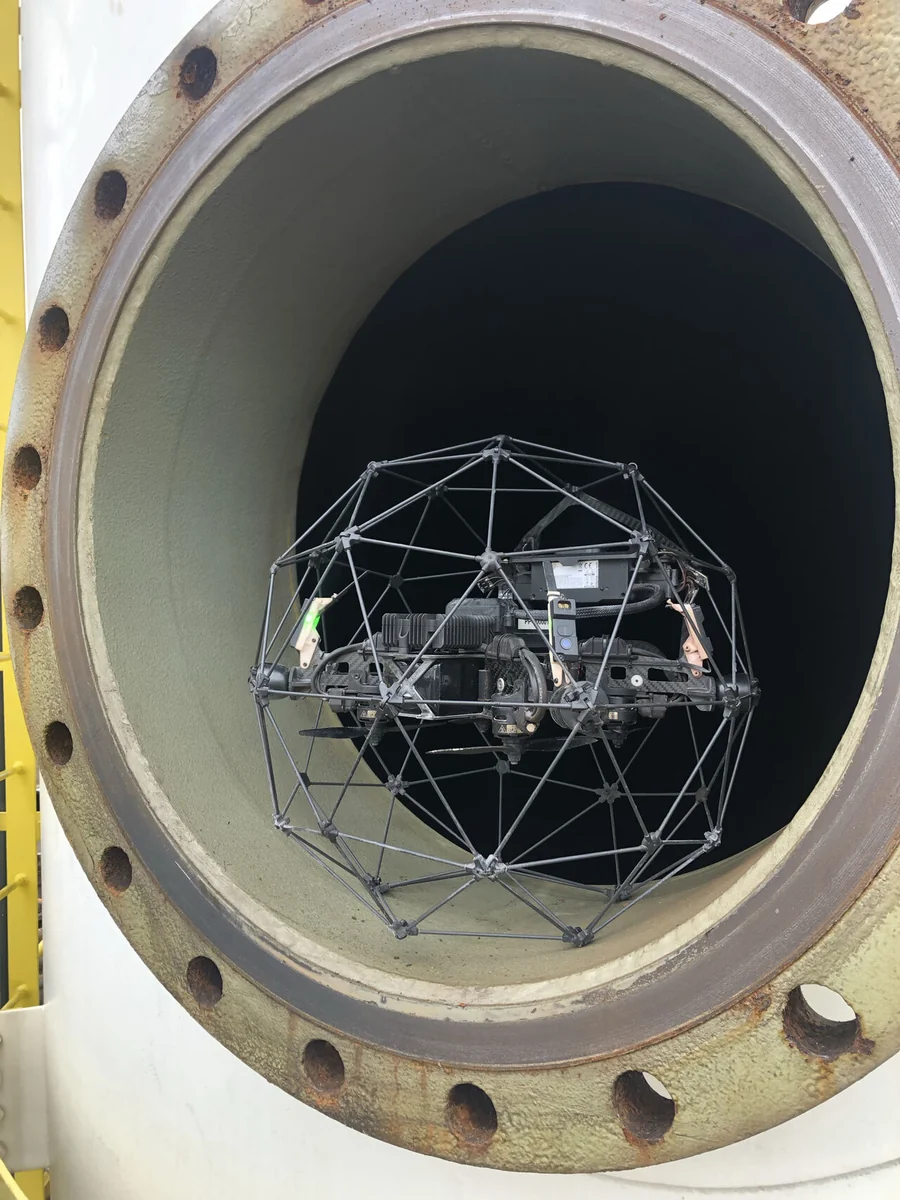

Other Advanced Technologies

- Automated ultrasonic testing, digital radiography and infrared thermography for precise diagnostics, failure analysis and continuous monitoring of industrial assets.

With cutting-edge equipment and a highly qualified team, Priner ensures the execution of advanced NDT in full compliance with technical and regulatory standards (ASME, API, ASTM, NR-13, among others), delivering safety, operational efficiency and extended asset life.

Galery

Contact us and request a quote