Hot Thermal Insulation

Hot thermal insulation serves two main purposes: minimizing thermal dissipation from equipment to the surrounding environment and preventing the exposure of hot surfaces in areas where people circulate.

Fixed Conventional Insulation

150°C to 1200°C (302ºF to 2192ºF)

We work with insulating materials designed for medium to high temperature ranges, from 150°C to 1200°C (302ºF to 2192ºF), offering custom solutions for a variety of operational demands. Our materials include Rock Wool, Ceramic Fiber, Aerogel, Expanded Perlite, Calcium Silicate and Refractory Linings.

We apply metallic claddings, such as aluminum and 316L stainless steel, for mechanical strength, weather resistance, and corrosion protection. We also offer non-metallic cladding options like ULVA and Stenca Pipe, which provide greater flexibility for complex areas and ensure high performance.

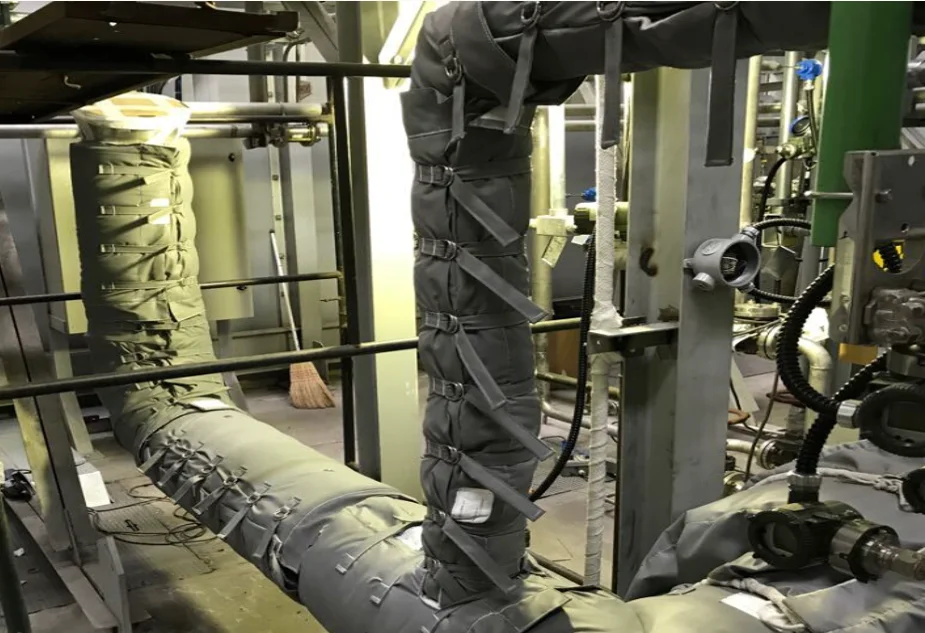

Removable and Reusable Insulation

30°C to 800°C (86ºF to 1472ºF)

These solutions are fully customized to match the operational environment, considering interference points and ease of daily application. Each system is dimensioned for thermal attenuation in compliance with standards such as N-894, which sets maximum surface exposure limits of 60°C (140ºF). By enclosing hot surfaces, the heat that would normally dissipate into the environment is retained and returned to the equipment, reducing the need for additional energy input.

Project calculations follow key international standards, including: ASTM C680 (Heat Gain and Loss); ASTM C201 (Thermal Conductivity).

- Warranty: 2 years

Galery

Contact us and request a quote