Priner has been a leader in maintenance engineering, industrial assembly, and infrastructure solutions for over 40 years. Based in Brazil, we are expanding into the U.S., bringing our expertise and commitment to excellence. As a public company listed on B3, we employ 7,000 professionals and operate from 12 offices across Brazil. We offer a broad portfolio of Integrity and Advanced Engineering Solutions for Industrial Equipment, ensuring the safety and reliability of your assets. Using advanced engineering tools like Ansys, Star CCM+, PV Elite, TWI RiskWise, and Caesar II, our team delivers tailored, reliable solutions that exceed client expectations. This portfolio is divided into four lines of work: - Advanced Engineering - Inspection and Risk-Based Inspection (RBI) - Removable and Reusable Thermal Insulation - Removable Passive Fire Protection We serve industries such as Oil and Gas, Petrochemical, Energy, Shipbuilding, Aerospace, Healthcare HVACR Systems, Motorsport, and Industrial Manufacturing. Our commercial representative in the United States is MRM Trading LLC. Contact us: Email: mrm@mrm-global.com Mobile: +1 (305) 748-5445 Office: +1 (786) 883-2929

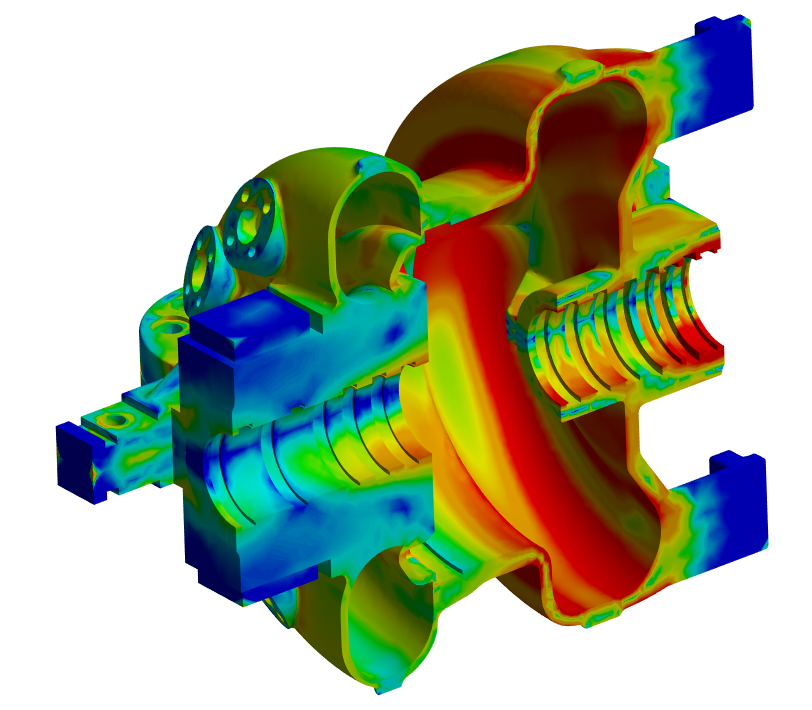

- Finite Element Analysis (FEA) using ANSYS; - Design by analysis; - Computational Fluid Dynamic (CFD); - Fitness-For-Service (FFS); - Pipe flexibility using CAESAR II software; - Structural analysis and design; - Design, calculation and analysis of buoyancy and stability of floating roofs for oil tanks by computer simulation. Click to learn more

Our thermal jackets make the daily routine of maintenance teams easier and ensure energy efficiency, high quality and safety. ISO 9001 certified and recognized by Lloyd's Register to develop removable and reusable jackets for industrial equipment. - Passive Fire Protection (PFP); - Thermal Insulation (Hot and Cold); - Jackets with Electric Tracing; - Acoustic Insulation. Click to learn more

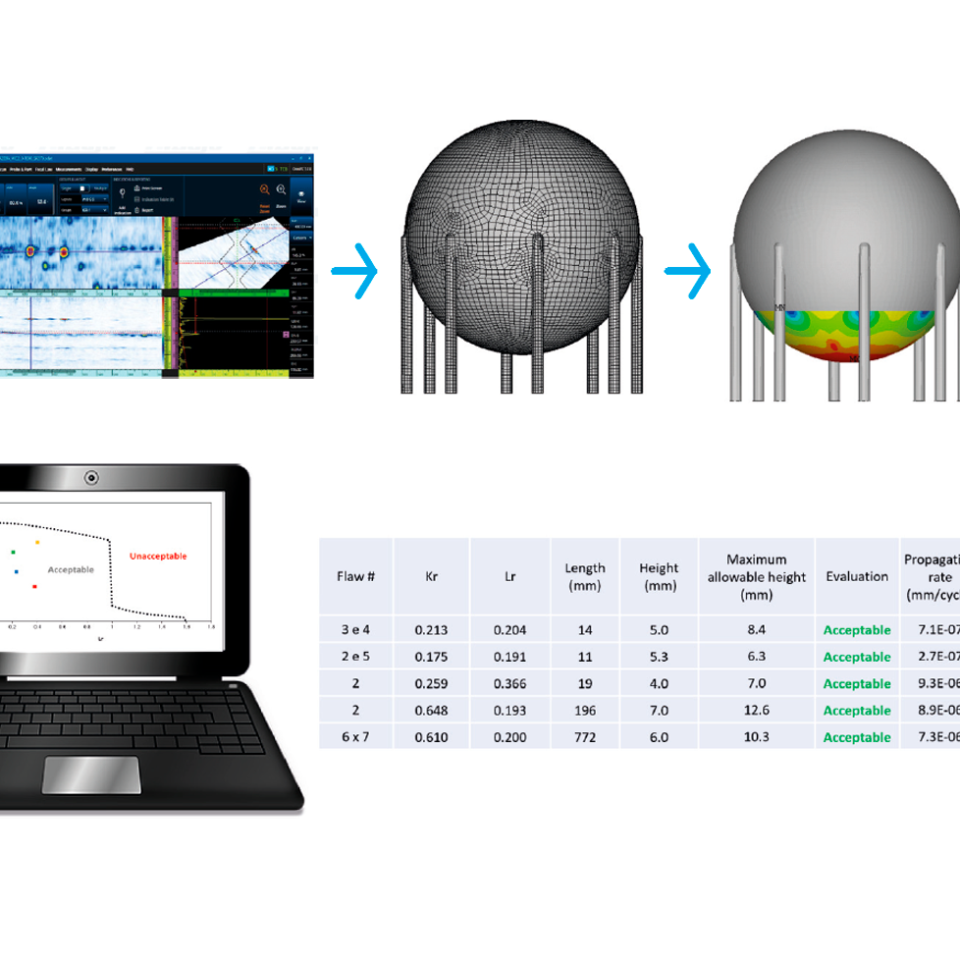

- Preparation of inspection plan; - Reconstitution of technical documentation and asset databooks; - Repair & alteration projects; - Advice and implementation of the RBI (Risk Based Inspection) program; - Design, installation and operation of SHM (Structural Health Monitoring) systems for damage prediction and monitoring; - Consulting services in inspection engineering by certified professionals according to API 510 (vessels), API 570 (piping), API 571 (damage mechanisms), API 580 (risk-based inspection) and API 653 (tanks) standards.

- Costumized protection for valves, actuators, pipes, vessels, trays and instruments; - Removable fire jackets ensure safe shutdown in an issue or a fire incidente; - Critical equipment and controls must remain below the failure temperature for the entire period specified by fire protection; - Explosion resistance with pressure up to 23.5 PSI (1,62 bar); - Access panels for maintenance and inspection; - Allows inclusion of gás and ventilation cooling system; - Type Approval Certification Lloyds registes.

- Fitness for service – API 579; - Design by analysis – ASME Sec. VIII; - Asset life extension; - Repair design using FEA; - Piping flexibility; - Structural steel design and calculation.

- Personal Protection, preventing acidental burns in the glowing sections of the exhaust outlets (Turbines, Flexible, Joints, Pipes); - Redcution of Heat Radiation in the Engine Room; - It will prevent premature re-sealing of Oil houses, preventing ruptures and leaks, wich could generate fires; - It will increase the useful life of sensors and other engine peripherals, vital for identifying overheating; - Our Jackets are non-combustible and do not generate smoke when exposed to fire.

- Design of reactors and flow equipment; - Solutions to reduce head loss and flow improvement in pipelines; - Fluid-structure interaction; - HVACR systems project, evaluation and optimization; - DEM analysis for mining conveyor systems, grain handling, particule mixing; - Reduction of pollutants and increase of combustion efficiency in boilers, furnaces and reactors; - Acoustic emissions and reduction of NVH in machinery, equipment and HVACR; - Aerodynamic for optimization of land, sea and aeronautical vehicles.

Lack of fusion, lack of penetration on weld, fatigue cracking, SCC, HTHA and other cracks/flaws detected on NDTs can be assessed and, in most cases, there is no need to repair. They can be calculated using the fracture mechanics method following the criteria of Standards BS-7910:2019 and API-579/FFS-1 Ed. 2021. Your equipment can operate safely even with the presence of these cracks.

The execution of all work starts and ends with Access, and we are specialists in this area.

Priner has extensive experience in Geotechnics, consistently combining modern solutions, high technical capability, and solid expertise in executing a wide range of services. One of the main technologies used by our company is the execution of injected piles, also known as pressurized anchoring.

The pressurized habitat is the ideal solution in terms of cost and operation at sites with strict safety requirements, such as offshore oil production rigs, refineries and petrochemical plants and terminals.

The Integrity Engineering and Inspection team at Grupo Priner is composed of qualified professionals and equipped with cutting-edge technology to deliver the best solutions in conventional and advanced inspection techniques for equipment assessment.

Efficient solutions for conventional and portable thermal insulation systems, firewalls and acoustic systems, offering maximum productivity and quality.

A qualified technical team develops tailor-made solutions in all market segments, taking into account the reduction of environmental risks and increase the projected life of the plants.

We offer a broad portfolio of Integrity and Advanced Engineering Solutions for Industrial Equipment in the United States, ensuring the safety and reliability of your assets.

Priner operates in the infrastructure sector with a focus on solving its clients’ structural issues while minimizing the impact on their operations.